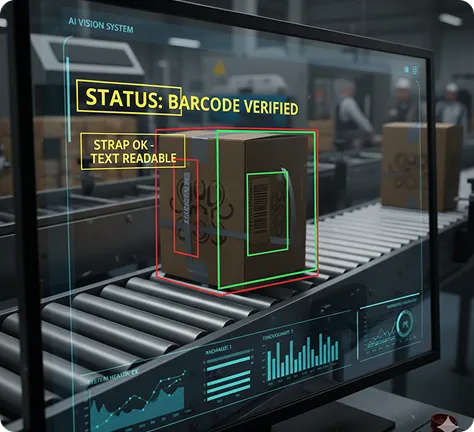

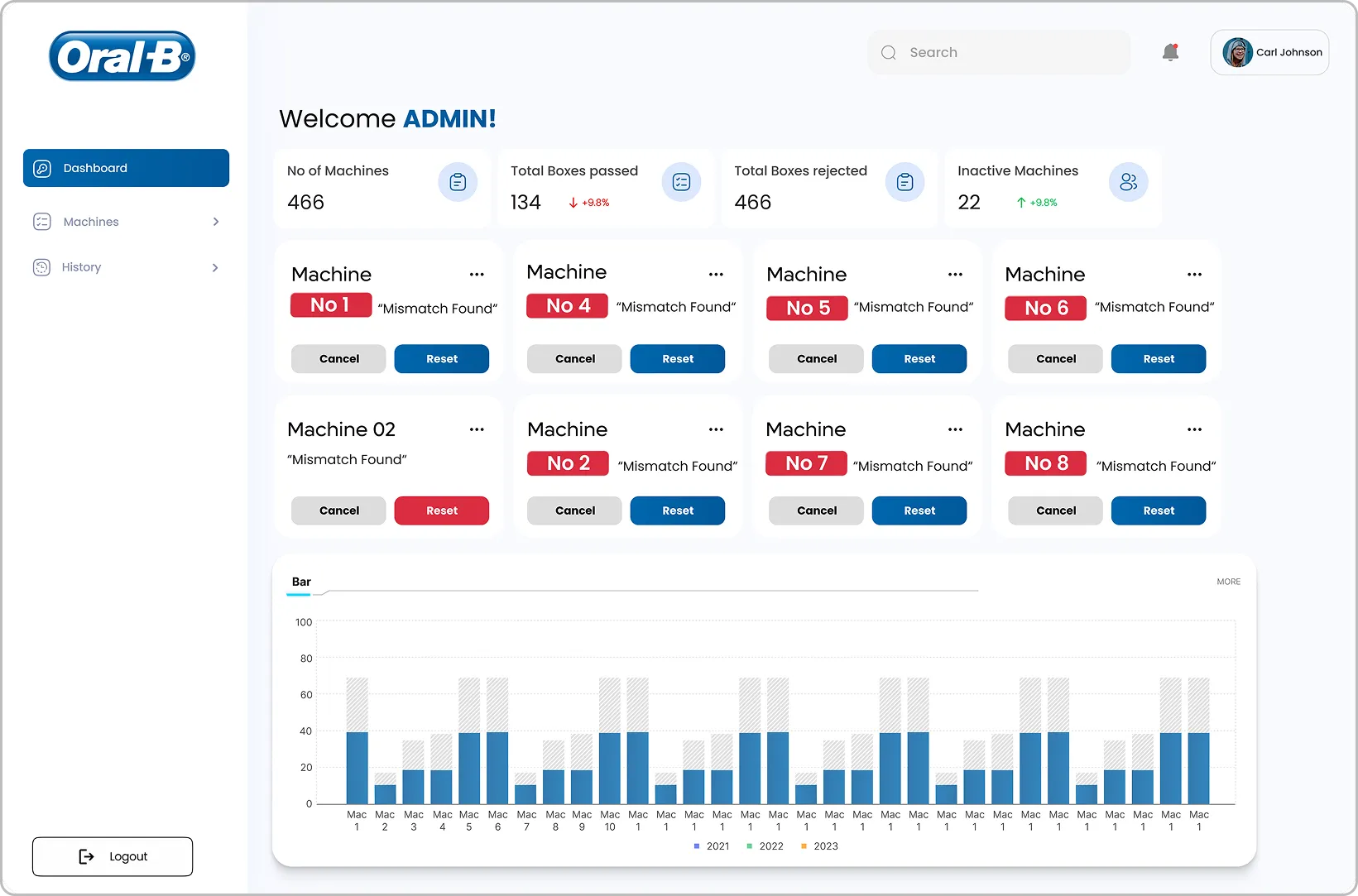

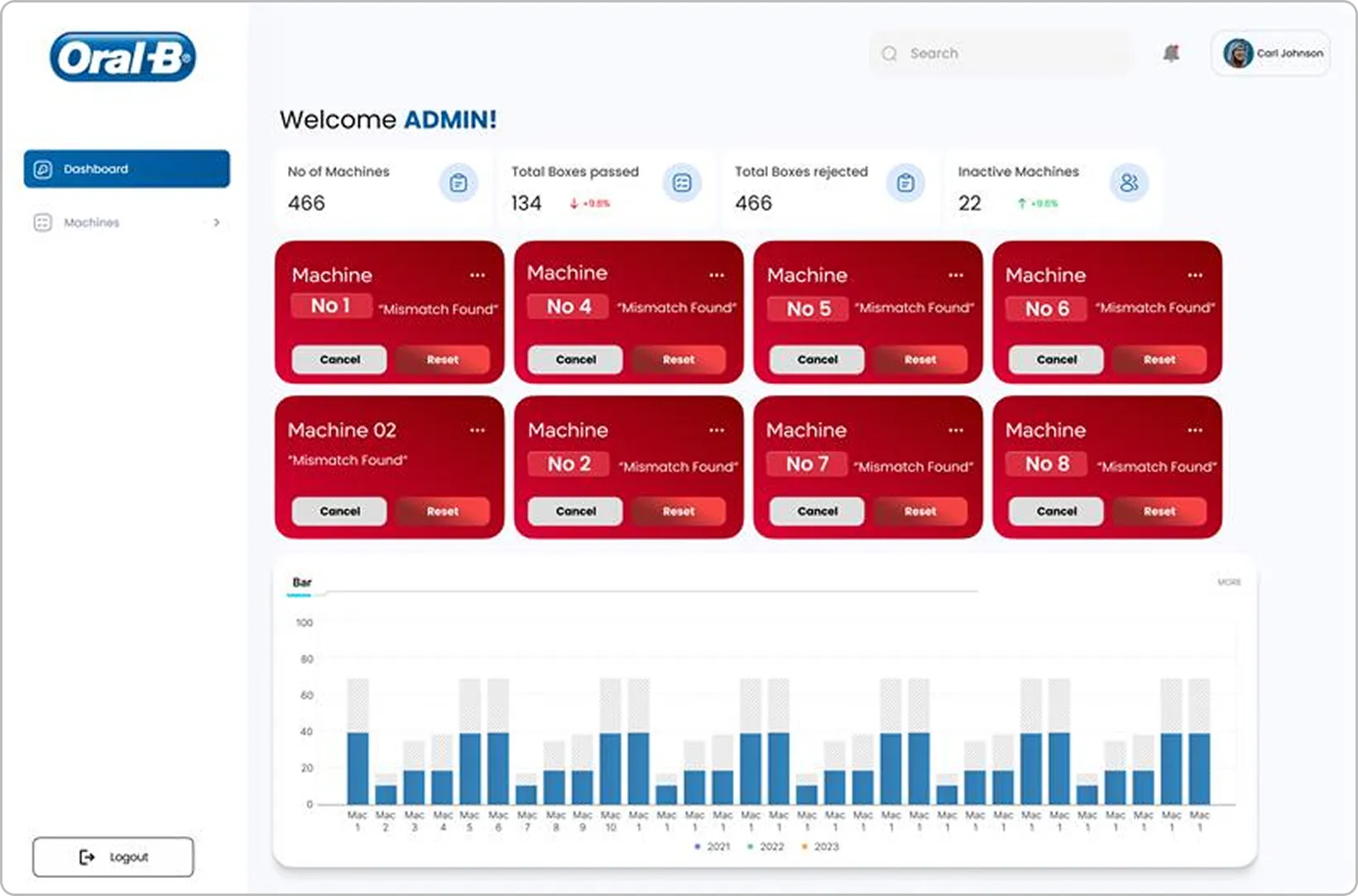

“Manual inspection couldn’t keep up with our production speed. Tentovision’s AI inspection ensured every Oral-B package met strapping, labeling, and barcode standards consistently — without slowing the line.” - Quality Operations Team, Oral-B

What happened ?

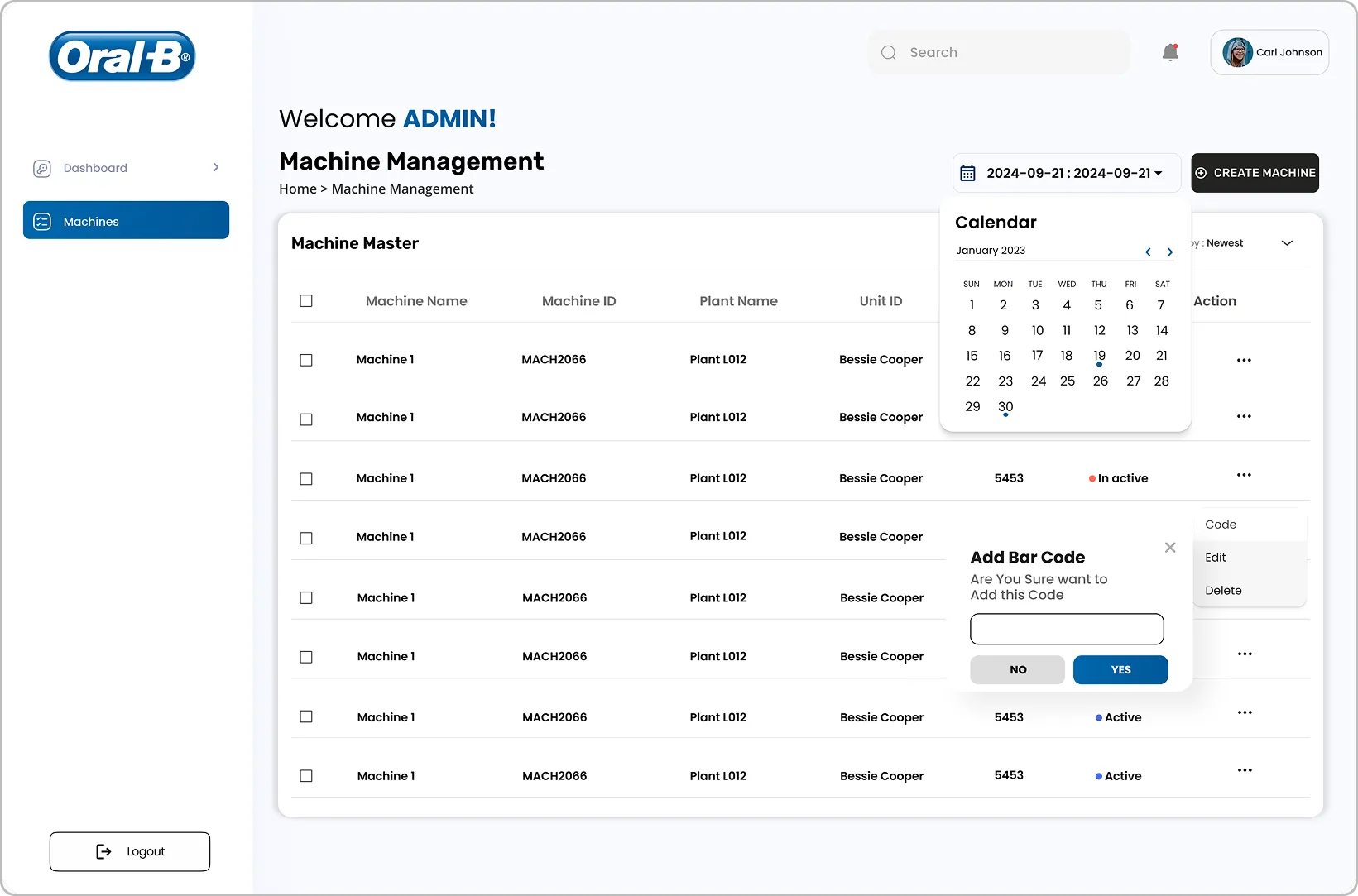

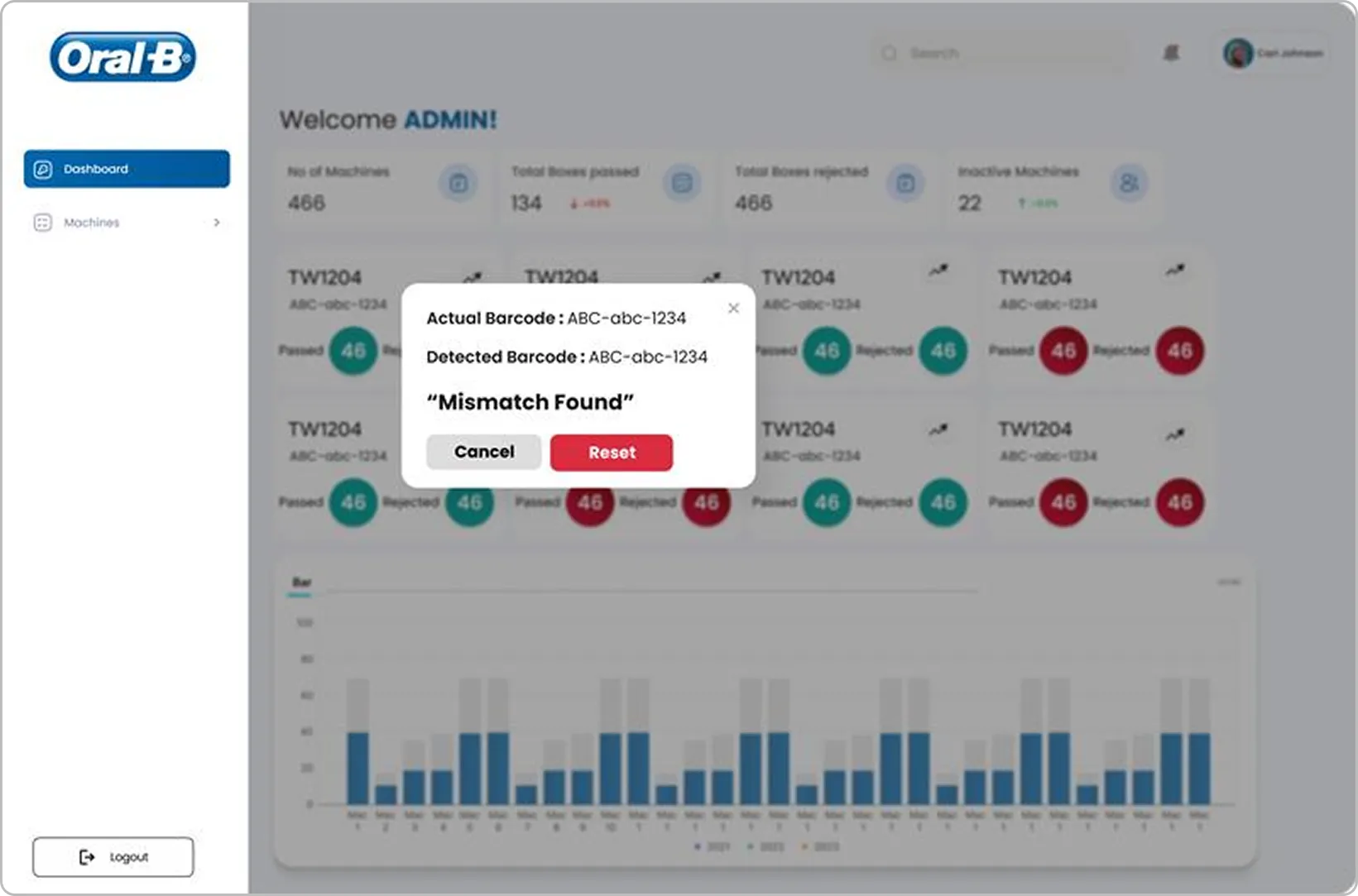

Packaging defects were hard to catch at full production speed. Manual checks failed to consistently validate straps, text, and barcodes. Errors surfaced only during audits or customer complaints.

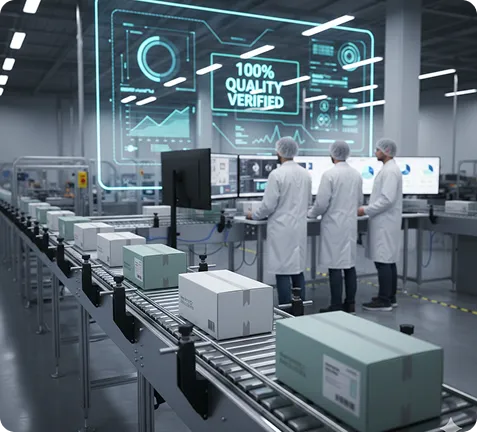

How TentoVision responded

AI models monitored each package in real time. Missing straps, incorrect text, or barcode mismatches were instantly detected. Faulty packages were flagged immediately before dispatch. Quality teams gained full visibility without slowing production.

.webp)